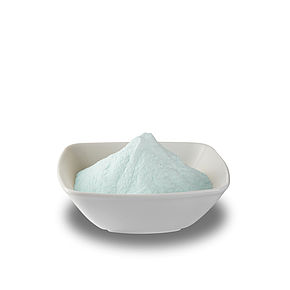

We spray vitamins and minerals as functional components in different ratios with various carrier systems. This facilitates amongst others the handling in industrial processing.

ISO 9001:2015

Uelzena Group

We spray vitamins and minerals as functional components in different ratios with various carrier systems. This facilitates amongst others the handling in industrial processing.

In the spray drying process of fat-soluble vitamins, the production of a stable emulsion of the liquid phase is a basic requirement in order to achieve a good solubility and shelf life of the final product. Furthermore, it ensures that the functional components are optimally distributed in the powder.

The powder structure of spray-dried vitamins and minerals is also very important for further processing, for example in pre-mixes. With our advanced spraying technology we can produce the required powder structures from fine spray products to agglomerates. With sophisticated zoning concepts and in-house analyses in our laboratory, we can also meet the complex quality requirements for infant food.

Related product (search) terms for spray dried vitamines and minerals:

Important information for the spray drying of vitamines and minerals:

We produce these products exclusively for our customers. We do not sell vitamins or minerals within the scope of our ingredients product range. Our service is the spray drying of customer raw materials such as vitamines and minerals on a contract basis. We are looking forward to your inquiry for your individual spray drying project.

Vitamins and minerals are used as additives in (functional) food and dietary supplements. They are often also an important component in baby and infant food.

Depending on the type of your spray-dried product and your downstream processing requirements, we offer a broad range of packaging options. Commonly bag-in-box systems, bags or big bags are used. Of course we can also use the packaging materials you delivered. Together we could also discuss and develop the optimal packaging solution for your product. Please contact us for details.

Kosher / Halal:

Some of our spray towers and production facilities are approved for Kosher and Halal production. The requirements are very complex and depend on the individual spray drying project. Whether we can convert your spray product into Kosher or Halal quality therefore requires prior testing.

Organic:

On request, we can also carry out contract drying according to the specifications for organic products after testing in individual cases.

Leadership through experience - our comprehensive know how and many years of expertise in spray drying processes makes us the ideal partner for your multi-faceted spray drying projects. Our strength is the customized development, control, organization and systematic approach of the production process for each and every sprayed product - from the individual preparation of preliminary steps including dissolution or emulsifying to the spraying process itself. With our highly qualified analytical laboratory and our sophisticated cleaning processes, we can guarantee a maximum degree of hygiene and safety.

This product is just one example from our specialized contract drying range of products. Our core competence is the drying of a broad range of individual products for our customers. The different product groups include protein hydrolysates, tea extracts, natural colors, flavors, soy sauce powders, yeast extracts, beta carotene, vitamins and minerals.

At our Uelzen drying facility, we operate five different spraying towers of various sizes that are equipped with different spraying technologies as well as with centrifugal or nozzle-type atomizers. In this way, we can meet multi-faceted customer requests and specifications. Take advantage of our decades of expertise and problem-solving competence for your spray-drying project.

We are a premium supplier to the food industry and our top priorities are the quality and safety of the products. Strict monitoring and control of our production processes by a certified quality management system are obvious in our company as are regular audits and certifications based on the most important standards. The implementation of comprehensive HACCP and zoning concepts, as well as continuous quality inspections of all products and raw materials in our specialized in-house laboratories are other important elements of our quality concept. We’ll be happy to provide more information on this subject. Please contact us.