26.07.2022 | The aim of producing particularly safe infant-quality products is of central importance in the design of our new Tower 12 spray drying plant. In addition to a sophisticated hygiene concept, this also includes ensuring safe production, both in terms of the product and for our employees.

The topics of occupational safety, ergonomics and employee protection were therefore integrated into the planning for the new plant from the very beginning in order to create not only optimum production conditions but also working conditions.

A not insignificant aspect of the planning was the most ergonomic possible design for the production environment, which includes, for example, the optimal design of traffic and walkways, safe and convenient access to machines and equipment, good lighting, or the correct placement of switches, controls, and work platforms. Avoiding the lifting of heavy loads, e.g. by using scissor lifts and other lifting aids, is also important for health protection. Likewise, spacious changerooms, sanitary rooms and recreation rooms in the new plant contribute to preventive health care for our employees.

In addition to a good fire and explosion protection concept, work safety in a spray drying plant also includes, in particular, extensive containment measures to prevent contact with dust and potentially hazardous substances.

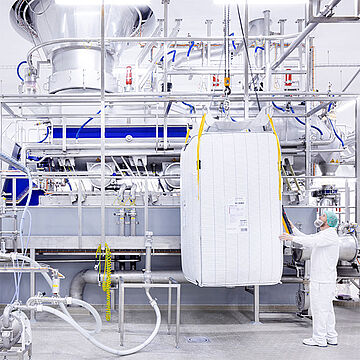

The feed section for active ingredients is therefore completely encapsulated and also operates with a powerful extraction system, so potential dust remains completely within the encapsulated space. The containers with the ingredients are opened in so-called glove boxes, which are operated from the outside using long gloves. The feed stations for carriers also have an extraction system and partial enclosure to minimize dust exposure.

The avoidance of dust is also an important component of the sophisticated modern hygiene concept of the new spray drying plant. The same applies to the extensive avoidance of water in the drying and packaging areas.

The plant is divided into different hygiene zones, from exterior to high care, which are strictly separated from each other structurally. They can be accessed through separate entrances with hygiene locks. Each zone has its own clothing and shoes for the employees, which remain within the zones. Pressure differences between the rooms prevent cross-contamination. Ventilation and filter systems separated according to hygiene zones supply the plant with conditioned air.

As for the employees, there is also a strict hygiene concept for materials such as raw materials and pallets. For example, pallets must be exchanged as soon as they move to another zone. The use of conveyors and crane rails also prevents contact with the floor when transporting materials.

For safe production, avoiding water in the production zone is the top priority. Sophisticated cleaning concepts keep all critical areas as dry as possible. Of course, wet cleaning cannot always be completely avoided, but if it is, it is carried out as safely as possible: Cleaning and drying of demountable plant components such as the sieves of the spray tower or the small packaging unit takes place in separate washrooms outside the white and high-care zones. The spray lances of the tower can be put through special sluices in the wall and cleaned in the adjacent room. Special wet cleaning lances are available for cleaning the spray tower itself and water leakage into the white area is prevented during tower cleaning.

During regular operation of the new plant, the hygiene concept will be permanently verified by continuous environmental monitoring. For parts of the plants, we are planning certification according to the strict "EHEDG" standard for hygienic plant design.